PWDM is used for packaging of optical module. It can realize the multiplexing of two communication signal, which expands the capacity of single fiber and achieves bi-directional communication. It is widely used in optical network upgrade and expansion, or introduce new comprehensive business (CATV, TELECOM, integration of three networks-PON+EOC) etc.

Key Features:

Low Insertion loss

Low PDL

High channel isolation

High stability and reliability

Applications:

WDM system

CATV

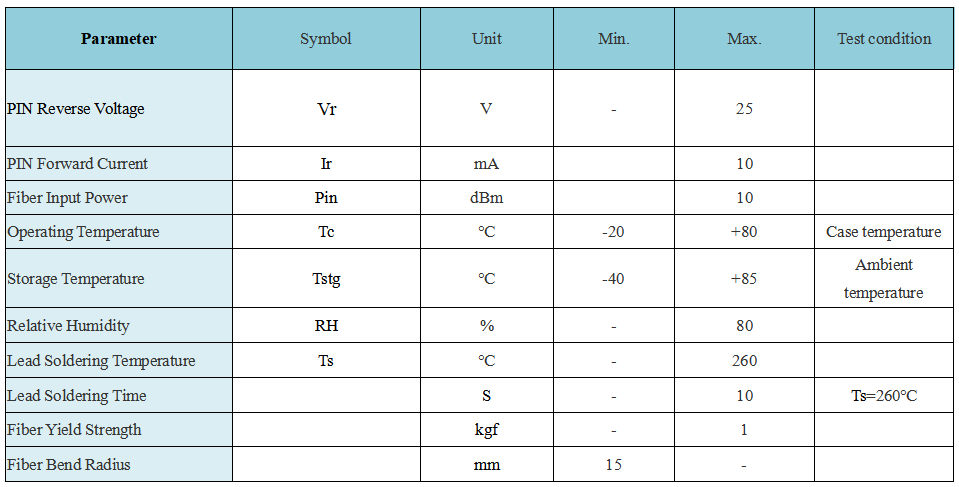

Absolute Maximum ratings:

Note: Beyond the scope of absolute maximum ratings can cause permanent damage to the device. If it has been a long time to use the device in the absolute maximum ratings may affect device reliability.

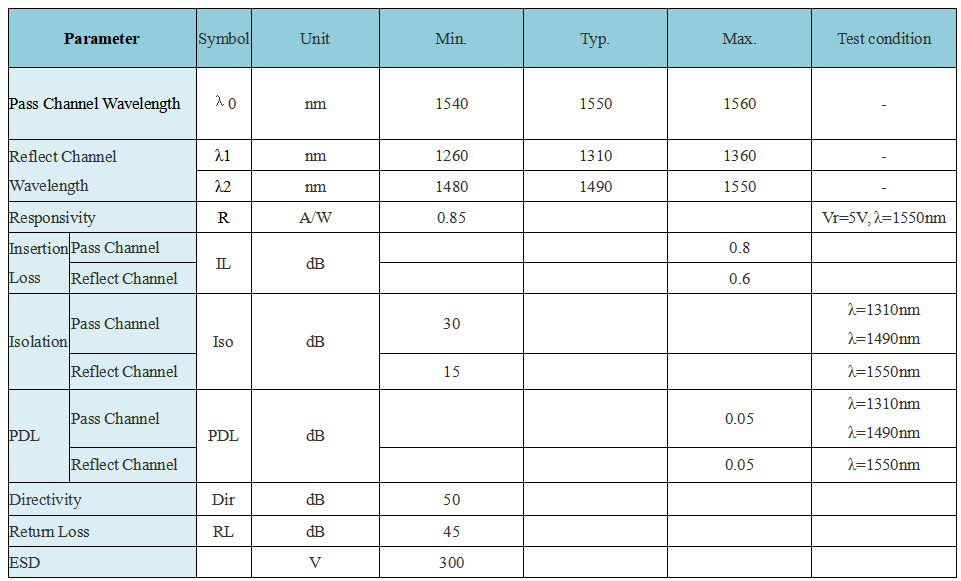

Optical and Electrical Characteristics:

(All measurements are at Case temperature of 25℃±3℃,VR=12V@1550nm unless stated otherwise.)

Second-order and third-order distortion test instructions:

1310/1550nm dual tone test, OMI = 40%, total received power P = 0dbm.

Note1: fm=548.5MHz, f1=109.25MHz, f2=439.25MHz,

Note1: fm=529.25MHz, f1=349.25MHz, f2=439.25MHz

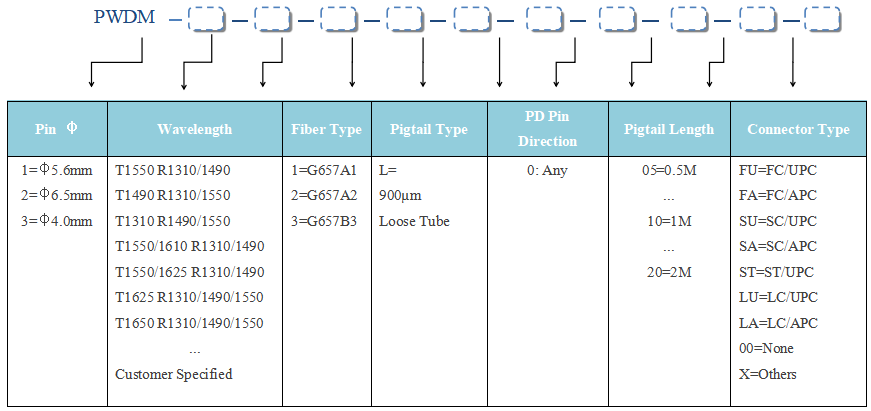

Order Information:

T=Transmission Wavelength, R=Reflection Wavelength,

1310±50nm, 1490±10nm, 1550±10nm, 1610±10nm, 1625±25nm, 1650±20nm

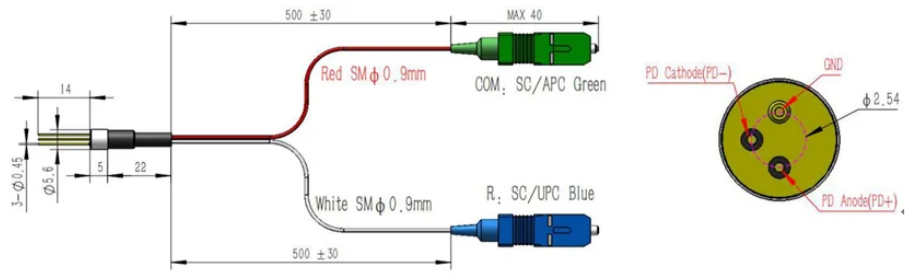

Package Dimension:

All dimensions are ±0.1mm unless otherwise specified (Unit: mm)

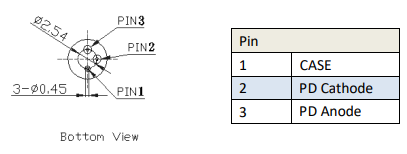

PD Pin Assignment:

Precautions:

Semiconductor chips are sensitive to electro-static damage. The module shall be packed with antistatic material for transportation. The working station and operators shall be grounded. Switching transients can cause electrical overstress (EOS) damage to the chips. EOS be may resulted from improper ESD handling, improper power sequencing, a faulty power supply or an intermittent connection. a. Operators should always use antistatic bands and clothing, electric conductive shoes, and other safety appliances while at work are highly recommended. b. Humidity in working environment should be controlled equal or above 40 percent RH. c. It is recommended that grounding mats be placed on the surfaces of assembly line workbench and the surrounding floor in working area, etc. d. When mounting this product in other parts or materials which can be electrically charged (printed wiring boards, plastic products, etc.), pay close attention to the static electricity in those parts.ESD may damage the product.

TEL:13995551051; Email: sales@cloudfiber.cn

TEL:13995551051; Email: sales@cloudfiber.cn